Expandcollapse

- Home

- Solutions

-

- All Materials

- Industries

-

-

- Aerospace and Defense

- Automotive

- Consumer Products

- Design Agencies

- Education

-

Accelerated development of education devices and health care products

-

-

- Resources

- About Us

- 123

Accelerated development of education devices and health care products

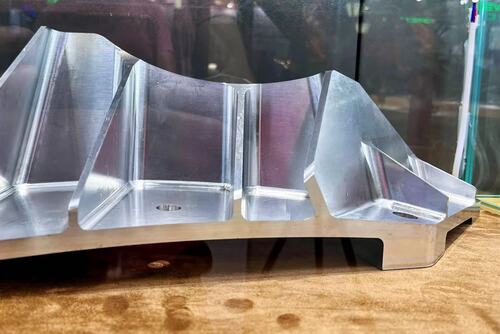

Aluminum stands out for its high machinability, durability, lightweight nature, and affordability, making it ideal for various parts across multiple industries.

Aluminum’s low density, strong mechanical properties, high conductivity, and corrosion resistance make it a top machining choice. Popular alloys like 6061-T651, 7075-T651, and 2024-T351 strike the perfect balance of strength, machinability, and cost in CNC machining.

Aluminum parts can be found everywhere, in a range of industries, especially automotive, aerospace, industrial equipment and machinery, and consumer and computer electronics.

• Automotive parts (light-weighting provides high strength-to-weight ratio)

• Housing, brackets, and other components for aerospace use that must support heavy load capacities but be light weight

• Fixtures, calipers, and a variety of other parts for industrial equipment

• Enclosures, panels, consoles, knobs, housing, and other applications for consumer and computer electronics

We offers several aluminum alloys in its long list of available manufacturing materials.

Aluminum 7075 T651 and T7: Benefits include high strength, hardness, low weight, corrosion resistance, and high heat tolerance.

Aluminum 2024 T3: This high-strength alloy offers a high strength-to-weight ratio and high corrosion resistance.

Aluminum 6061 T651: Though not as strong as other types of Aluminum, this alloy offers the best corrosion resistance and appearance after anodizing.

In this guide to CNC machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

How to create efficient, manufacturable metal and plastic parts through design considerations, material selection, and streamlined machining processes.

With a universe of metal and plastic options, let your machined parts function determine material.

Workhorse Metals

for Machining and 3D Printing. Light weight and strength help aluminum and titanium excel for 3D-printed and machined parts.