Expandcollapse

- Home

- Solutions

-

- All Materials

- Industries

-

-

- Aerospace and Defense

- Automotive

- Consumer Products

- Design Agencies

- Education

-

Accelerated development of education devices and health care products

-

-

- Resources

- About Us

- 123

Accelerated development of education devices and health care products

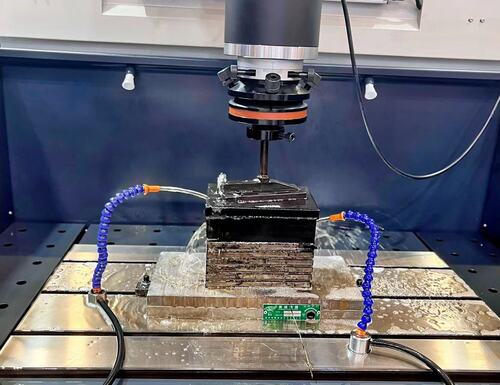

3/4/5 - axis machining capabilities for simple & complex geometries. Tolerances ±0.010 mm(±.001 in)

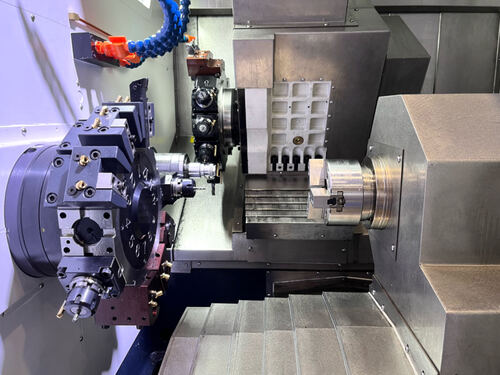

Capabilities of standard and live tooling for cylindrical parts including pins and shafts. (Tolerances ±0.010 mm(±.001 in)

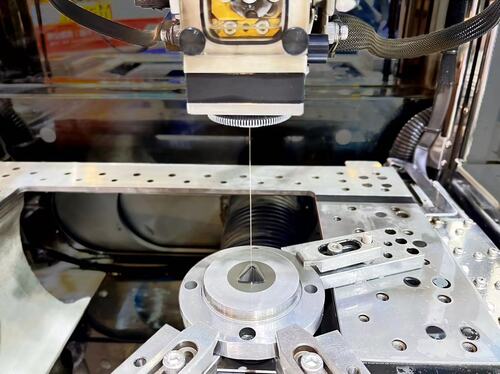

Non - contact material, achieve precision deep cutting in conductive materials such as hardened steel and carbide. (Tolerances ±0.0010 mm(±.0001 in)

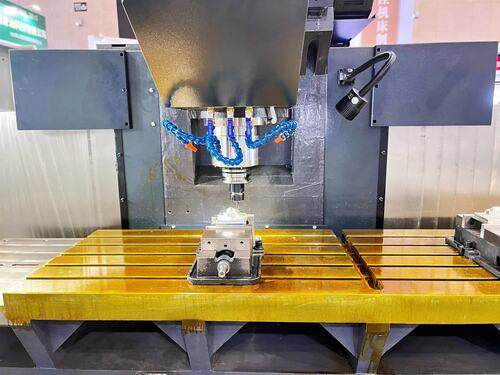

Precision machining solutions optimized for high - tolerance component production. Tolerances ±0.0010 mm(±.0001 in).

In this primary design and programming process. Because of our years of production and experience, we can sensitively and quickly find out whether there are any design problems in the drawings you come.

We must make sure solve the problem in the tooth eruption stage to ensure that our later production goes smoothly and the customer’s project can be completed perfectly, thereby achieving a win-win effect.

Details:

After the Design and Programming, we need to prepare the Material. At this stage, we must purchase materials strictly according to the customer’s requirements. We can also choose more suitable materials for you. The appropriate material is selected based on the specifications of the part, such as mechanical properties, thermal resistance, and machinability.

The CNC machine is set up according to the specific job requirements. This includes installing the correct tools, setting up the workpiece, and configuring the machine parameters.

In this process, we must strictly implement it to ensure that customers’ products are finished with high quality.

This is the core of CNC machining, where the machine cuts, drills, mills, or grinds the material to form the desired part. Multiple operations may be required depending on the complexity of the part.

Details:

After machining, the part undergoes a rigorous inspection process to ensure it meets the required specifications and tolerances.

Details:

Details:

Details:

Once the parts are fully processed and inspected, they are carefully packaged and prepared for shipment to the customer.

Details:

We begin by listening to your vision and requirements, gaining a deep understanding of your unique needs.

Experience precision from the very beginning with our meticulous design and prototyping process.

Watch as we bring your concepts to life with efficient production and timely delivery.

At TechTune CNC, we offer a range of services that provide improved efficiency, cost savings, and superior quality. Our team of experts is dedicated to delivering customized solutions that meet your exact specifications.

Boost your manufacturing operations with efficient and reliable services.

Experience the TechTune CNC difference for yourself today.

TechTune CNC has exceeded our expectations in delivering high-quality CNC parts that perfectly match our specifications. Their commitment to punctual deliveries and competitive pricing has made them our trusted partner in manufacturing excellence.

John Doe CTO, ABC Manufacturing

Webflow

Find answers to common questions about our services, turnaround times, material capabilities, and order processes.

TechTuneCNC provides a variety of services primarily focused on CNC (Computer Numerical Control) machining and related technologies. While specific offerings may vary, typical services provided by companies in this field often include:

For the most accurate information regarding TechTuneCNC’s specific services, it is best to visit our official website or contact us directly.

About TechTuneCNC’s turnaround time for their services. Turnaround times can vary based on several factors, including the complexity of the project, the type of service requested, current workload, and material availability.

TechTuneCNC typically works with a variety of materials. materials include:

For the most accurate and detailed information regarding their capabilities and material options, it’s best to contact us directly.

TechTuneCNC’s order process follows these steps:

Yes, you can typically request a quote from TechTuneCNC. To do so, you would generally need to provide specific details about your project, including:

To initiate the quote request, visit our official website and look for a “Get a Quick Quote” section or contact our sales team directly via email or phone. We will guide you through our specific process and provide an accurate quote based on your requirements.